Our Services

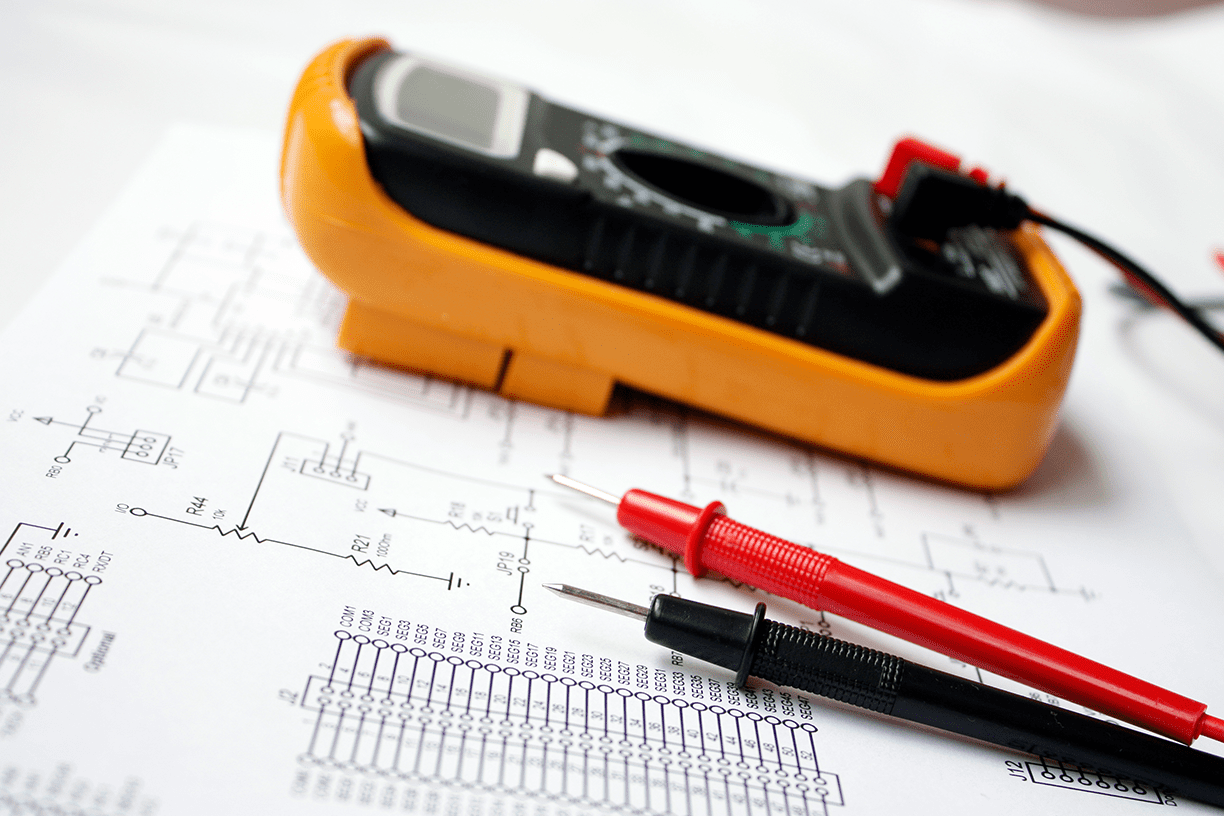

We provide a full scope of electrical and automation engineering and consulting services under one roof, driven by industry-best knowledge and fluid collaboration. We take time to develop a deep understanding of our clients’ businesses and facilities so we can design, refine, and implement solutions that will have the greatest possible impact. Whether in need of executing a turnkey project or a partner to serve as an extension of your in-house team, we are ready to get to work engineering efficient, cost-effective, and flat-out better results.

EXCEL BY THE NUMBERS

MARKETS WE SERVE

Our MarketsAcross four decades, we have developed extensive experience across a focused range of verticals, building our knowledge and expertise to serve industrial facilities throughout the country. From life sciences and consumer products manufacturing to oil and gas and power generation and transmission, our team has established a deep understanding of countless businesses, processes, and sites within our core markets – and we’re ready to get to know yours, as well.

Technical Minds. Creative Solutions.

Since 1990, we’ve remained intensely focused and invested in understanding how our clients operate at every level. It’s this attention to detail that has allowed us to produce higher-quality work and to establish longer-term partnerships with businesses like yours. Get to know our story and why we’re the only engineering firm capable of delivering on your most challenging and complex objectives.