Control the flow – select an appropriate valve trim

Normally when the process or mechanical engineer designs the process and selects the individual components, they may not necessarily select the proper trim characteristics that would properly complement the control design.

A valve and trim selection training course could cover several days and will not be attempted in this edition.

Things that should be considered in the valve characteristic selection are linearization of the process flow or linearization of the secondary process that impacts the main process.

The first consideration is to determine the required size of the valve that would support the particular application. In this case we must know the pressure differential available to the control valve over the desired flow range of the process. The first calculations need to be performed at maximum design flow conditions to determine the differential pressure available for the control valve. This will allow the engineer to select the maximum Cv (effective valve coefficient of flow) needed for maximum design flow. If the pumps supplying the flow can degrade and lose their available head or if the process piping can foul and reduce the available differential pressure to the valve, then considerations should be made to increase the size of the valve (Cv) to accommodate the system deterioration.

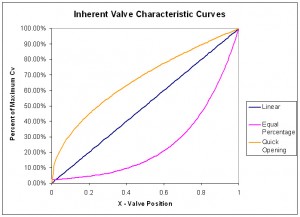

Valve trim can be ordered with several valve position/Cv characteristics. The most common are Linear, Equal Percentage, Quick opening and Custom.

If the system has high turndown and requires uniform controllability over the major flow range then consideration should be given to Equal Percentage characteristics.

Equal Percentage Characteristic:

A flow characteristic that, for equal increments of rated valve travel, will ideally give equal percentage changes of the flow (Cv). The percent of flow versus percent of valve position follows approximately:

%Flow = 10 * (10^(VP/96.0252))-10

Where:

%Flow = Percent of flow at maximum Cv

VP = Percent of valve position (0 – 100%)

The equal percentage characteristic provides a small change in valve Cv for a change in valve position near the closed end. Equal valve position movements result in equal percentage changes in the Cv of the valve. Near the open end of the valve large changes in Cv occur for similar changes in valve position. It should be noted with all valves that there may be some discontinuity between the valve full closed and its initial crack-open position.

Linear Characteristic:

With this trim the Cv of the valve will change uniformly as the valve position is increased. The Cv follows the following equation:

%Flow = VP

Where:

%Flow = Percent of flow at maximum Cv

VP = Percent of valve position (0 – 100%)

From Wikipedia

Custom Trim:

If the control engineer analyzes the system flow losses and identifies the desired process gains for the control of the process over the system operating range, he can define the Cv’s required over the control valve position range. Once these Cv’s are determined he can then order a control valve with the specific characteristics required to linearize the gain of the process. Ordering custom trim is generally more expensive than a predefined trim but in some cases can provide better control of the process.

Quick Opening:

Quick opening trim is seldom specified for flow or other continuous process control. This trim is generally used as an automatic isolation or for quick opening when a fast release of the retained process is needed. (Puffed rice is shot from cannons.)

Next time – Extend the flow range of high turndown processes with staged valves.