What is an Arc Flash?

An arc flash is the light and heat produced from an arc between one live electrical conductor and ground or between two live conductors. The arc travels through ionized air, also known as plasma, which turns the normally nonconductive air into a conductive path. The plasma temperature can reach 20,000 Kelvin (or about 35,000 Fahrenheit). That is hotter than the surface of the sun!

With that extreme temperature, the “flash” is violent. High-power arc-flash faults are electrical explosions that release a great deal of energy. That energy combines radiant heat, intense light, and high-pressure waves.

When an arc flash occurs, the instantaneous temperature increase rapidly expands the air volume. The resulting pressure wave can blow you off your feet and damage or destroy anything in its wake. The accompanying radiant energy burns dramatically.

High temperatures can also change circuit components from solid to vapor. For instance, if your conductor is copper, it would instantly vaporize at this arc flash temperature. This further adds to the destructive power of the arc flash. The vaporizing copper expands to over 60,000 times its original size. This significantly increases the pressure wave.

Our Arc Flash Consulting Process

We take a comprehensive, end-to-end approach to arc flash studies:

Arc Flash Studies Equipment Scope:

We can tailor the scope of the study to meet your requirements. Our typical Arc Flash study will include the following types of equipment for those portions of the power system included in the studies:

- Unit Substations.

- 480V switchgear, power panels, and motor control centers

- 480V control panels and disconnects fed from 60A or larger breakers

- 240V and 208V panels.

- 240V, 208V, and 120V control panels and disconnects fed from 60A or larger breakers

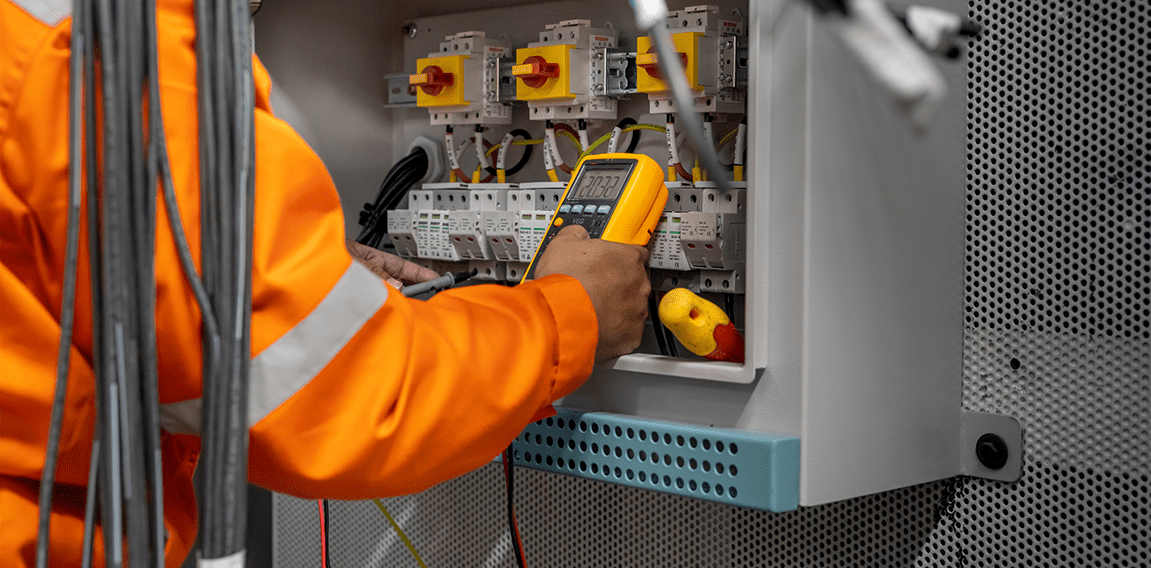

Data Collection

Our team will come to your site fully prepared with PPE and training to open energized electrical panels and collect data from Main and Feeder breakers and wire sizes and lengths so that we can accurately model the electrical system.

System Modeling and Arc Flash Hazard Analysis

Using industry-standard software, our engineers model your power distribution system to simulate fault conditions and calculate incident energy levels. We determine PPE requirements, calculate arc flash boundaries, and label equipment according to NFPA 70E standards.

We will model the entire power distribution system, including modeling motor contributions to accurately reflect the existing conditions, including individually modeling all motors 50HP and larger. Motors smaller than 50HP will be modeled within groups unless fed from a protective device larger than 60A and have a local disconnect requiring a label. We will also perform short-circuit and device evaluation studies with a contingency level of 250MVA for the utility system short-circuit contribution. Further analysis will be conducted for any underrated devices at the 250MVA level to determine whether they are properly rated for the actual utility contribution.

We review miscoordinated overcurrent protective devices based on the arc flash results, which flag devices with miscoordinated protective devices at the arcing fault level. We will also review main switchgear relay/breaker overcurrent settings and fuses and make recommendations in instances where changes could significantly lower arc flash incident energy levels and/or improve coordination with downstream equipment.

Labeling & Documentation

We will provide several example labels that can be customized to fit your needs. Once you select a label format and the arc flash study is complete, our team will apply the durable arc flash labels to all equipment included in the arc flash study, which will likely require inspection or maintenance while energized.

We will update CAD one-line drawings based on field information that can be safely verified, including all distribution panels, feeder information greater than 100A, conductor length, conductor size, short-circuit data, arc flash PPE category, and switchgear breaker/relay setting information. We will also update the AutoCAD panelboard schedules based on field information that can be safely verified, including updating feeder information greater than 60A, breaker setting information, and short-circuit information from the study.

Finally, we will deliver an Arc Flash Final Report that will include the following:

- Executive summary of assumptions, findings, and recommendations

- Arc flash summary report

- Short circuit summary with TCC Curves

- Device evaluation report

- Protective device settings reports

- Input Data Report

- Model one-lines

- Arc Flash Study Options Page

We're ready to help with your next Arc Flash Study.

Ensure electrical safety and NFPA 70E compliance with expert arc flash consulting and hazard analysis from Excel Engineering. Whether you need a complete arc flash study or a 5-year review, our team is ready to get to work.

Contact us now!

"*" indicates required fields